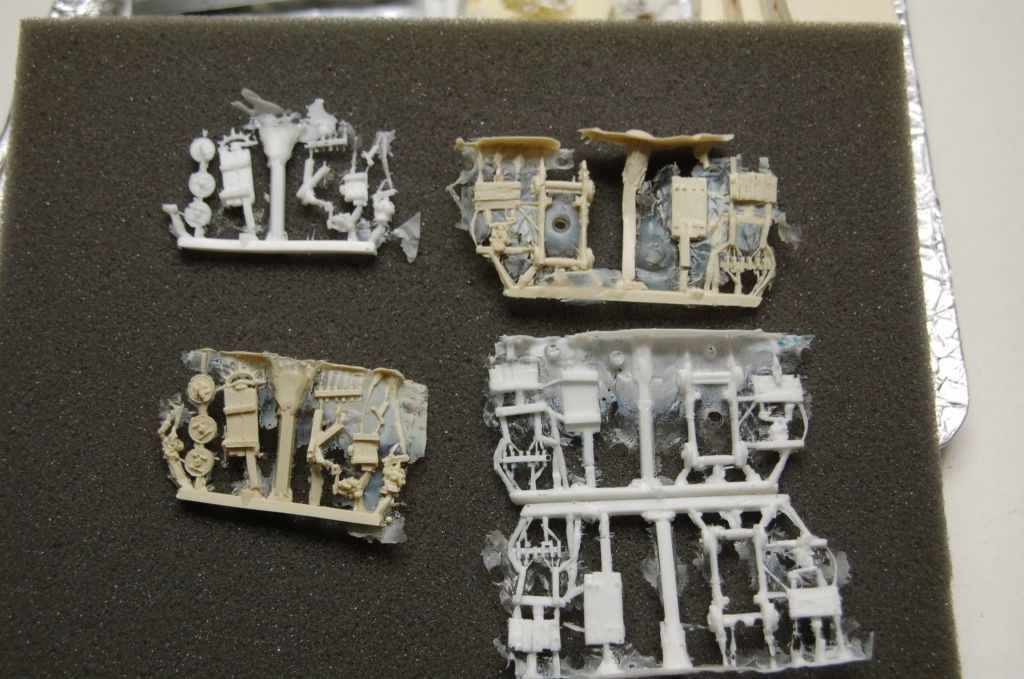

Here's a picture of the sprues I've cast for the pump wagons:

As you can see, all the parts of the model were cast! As it turns out, I had to widen the channels that carried the resin. I also widened the air vents. As a result, itis much easier to get the resin into the mold.

I use a syringe to inject resin into the mold. Previous to these attempts, there was resistance in getting the resin into the mold. Some resin leaked out of the bottom of the mold. Now the resin flows much more easily, and there is no resin leaking out of the bottom of the mold.

For this set of castings, I heated up my molds to 150 degrees F. Prior to heating, I lightly coated the mold faces with silicone oil. One the second (and third) castings, I used talcum powder. I think all this helped reduce the amount of air bubbles in the cast parts.

I also found a new way to hold the two halves of the mold together. I use two sets of wooden sticks (one stick on each side of the mold), with rubber bands providing the force to clamp the mold shut. I use one set near the bottom of the mold, and the second set near the top. This works very well, but I want to replace the rubber bands with screws and wingnuts to make it easier to use the clamps.

I found that I can cast the wagons with the tan resin, which is a bit stiffer when it is cured.

I suppose the next thing to do is to assemble one or two of these wagons to show you all the finished result.

Some notes for those of you who might want to try some resin casting. Here are some things that do not work too well: First, overheating the molds is bad. Any trapped air bubbles will expand because of the heat. Second, vacuuming resin can be problematic, and here's why: The vacuum causes those trapped air bubbles to expand. If the resin isn't completely liquid, the air bubbles will be trapped in their huge form. Third (and last), if you have to bake the casting in the mold, make sure that you wait until the resin has cured. Something about heat making the air bubbles expand.

The other thing I did for these casting was that I mixed 1/4 ounce of the A&B together to get 1/2 ounce of resin. I think that smaller quantities than this make it hard to stay within the resin's tolerance of the ideal 1:1 ratio of the A to B.